In the food industry, hygiene and safety are paramount. Frequent cleaning in production environments requires push buttons to possess excellent waterproof performance to ensure long-term, stable operation. As a critical component in equipment operation, the quality of push button switches directly impacts production efficiency and food safety. So, how do you choose the right waterproof metal push button switch?

1.Waterproof Rating: IP67 or IP68?

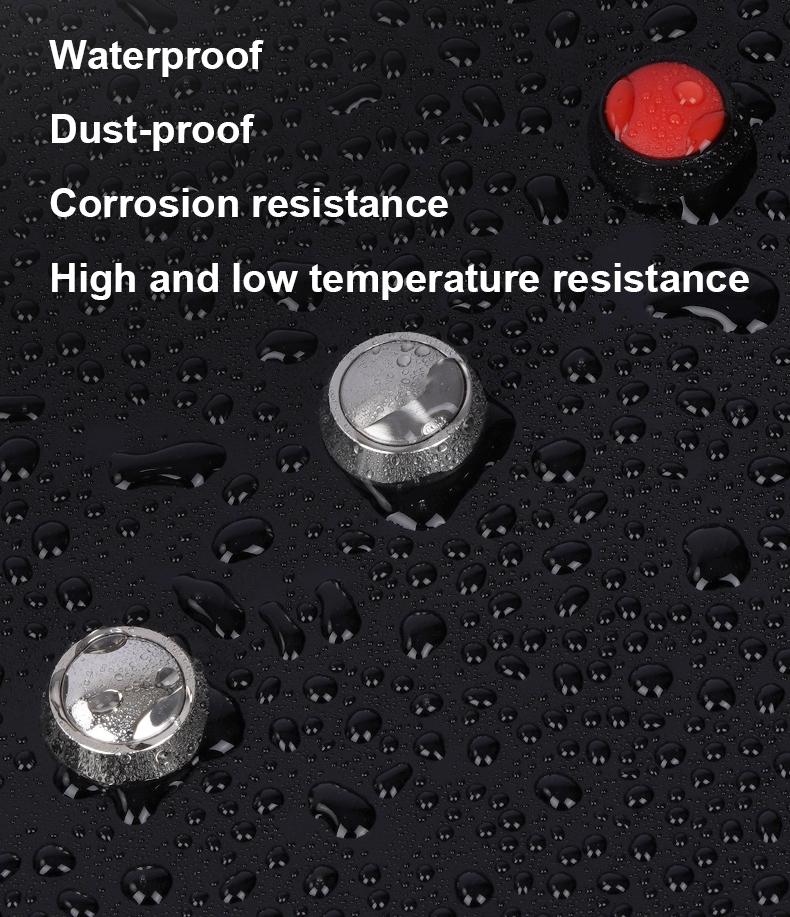

The IP rating is a key indicator of a push button switch's ability to resist water and dust. In the food industry, it's recommended to choose products with an IP67 rating or higher. IP67 means the switch can withstand immersion in water up to 1 meter for 30 minutes without damage, making it more than adequate for splashes and brief immersion during routine cleaning.

For specialized applications such as direct water washing, IP68-rated switches offer increased reliability and can withstand extended, deep submersion. For example, in meat processing plants, where equipment frequently requires thorough cleaning, IP68 waterproof metal push button switches are more suitable for such environments and ensure proper operation.

Our company's products meet IP68 ratings.

2.Material Selection: Stainless Steel or Aluminum Alloy?

Metal push button switches are primarily made of stainless steel and aluminum alloy. Stainless steel offers excellent corrosion resistance, effectively withstanding the acids and alkalis encountered during food processing and remaining rust-free even under harsh conditions. Aluminum alloy is relatively lightweight and cost-effective, while also offering some corrosion resistance. However, stainless steel performs better in highly corrosive environments.

For example, in kimchi processing plants, where highly concentrated brine is highly corrosive, waterproof stainless steel push button switches are an ideal choice, significantly extending the lifespan of the equipment.

3.Operational Ease: Button Feel and Clarity?

Operational ease is also crucial. A good button feel enables operators to maintain efficient operation over extended periods and reduces the risk of misoperation. Button travel and feedback should be moderate, ensuring smooth pressing and releasing. Furthermore, button labels should be legible even in humid and foggy environments. Our push button switches utilize laser-etched marking technology, which is not only clear and wear-resistant, but also effectively resists fading from prolonged contact with water and detergents. In bakeries with high humidity, clear markings help workers operate equipment quickly and accurately, thereby improving production efficiency.

4.Brand and Certifications

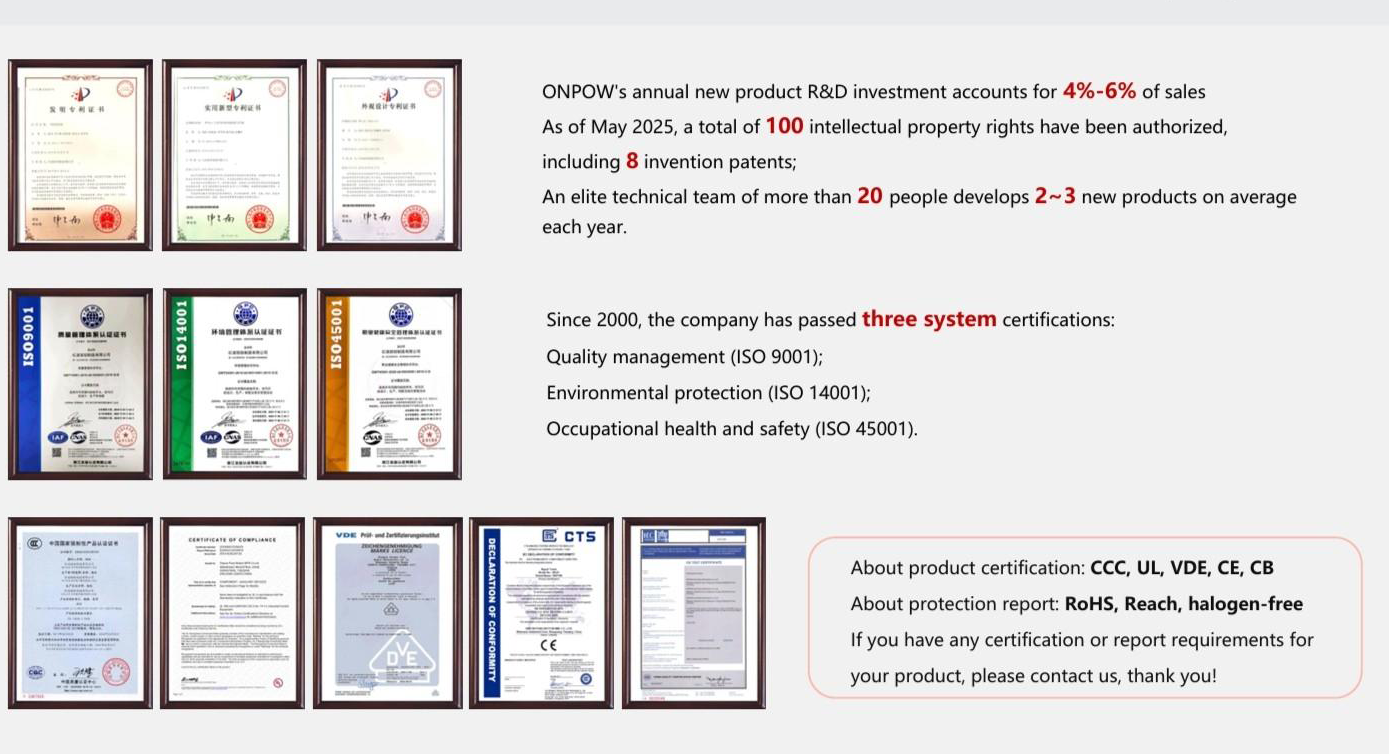

Choosing a reputable brand of waterproof metal push button switches can greatly guarantee product quality and after-sales service.

ONPOW PUSH BUTTON MANUFACTURE CO,.LTD., founded in 1988, is a technology-based company specializing in the research, development, and production of push button switches. Their products should also possess relevant certifications. For example, CE certification indicates compliance with European safety, health, and environmental standards, while UL certification is a product safety certification from Underwriters Laboratories (UL) in the United States. These certifications provide strong assurance of product quality and safety. Push button switches with CE and UL certifications are widely recognized worldwide and can be used with confidence in both domestic and exported food production equipment.

In short, when selecting a waterproof metal push button switch for the food industry, consider a variety of factors, including waterproof rating, material, ease of use, mounting method, brand, and certifications. Only then can you choose the right push button switch for your food production equipment and ensure a safe and efficient production process.