When it comes to medical equipment—like diagnostic machines, surgical tools, or patient monitors—every part matters. Metal push button switches, which control key functions (such as starting a scan or pausing a device), need to be reliable, safe, and long-lasting. But with so many options, how do you pick the right one? Let’s break it down simply, using ONPOW’s medical-friendly metal push buttons as a practical example.

1. Prioritize “Durability” – It’s Non-Negotiable for Medical Use

Medical equipment runs for hours daily, and buttons are pressed hundreds of times. A flimsy switch can break mid-operation, causing delays or even risks. So, look for:

- Long service life: ONPOW’s metal push buttons have over 20 years of production experience (they launched their first metal series, GQ16, in 2004). Their switches are built to handle frequent presses without wearing out, which is critical for busy hospitals

- Tough materials: Metal shells (like aluminum alloy) resist scratches, impacts, and even chemical cleaners (common in medical settings for disinfection). Unlike plastic, metal won’t crack easily if accidentally bumped by equipment or staff

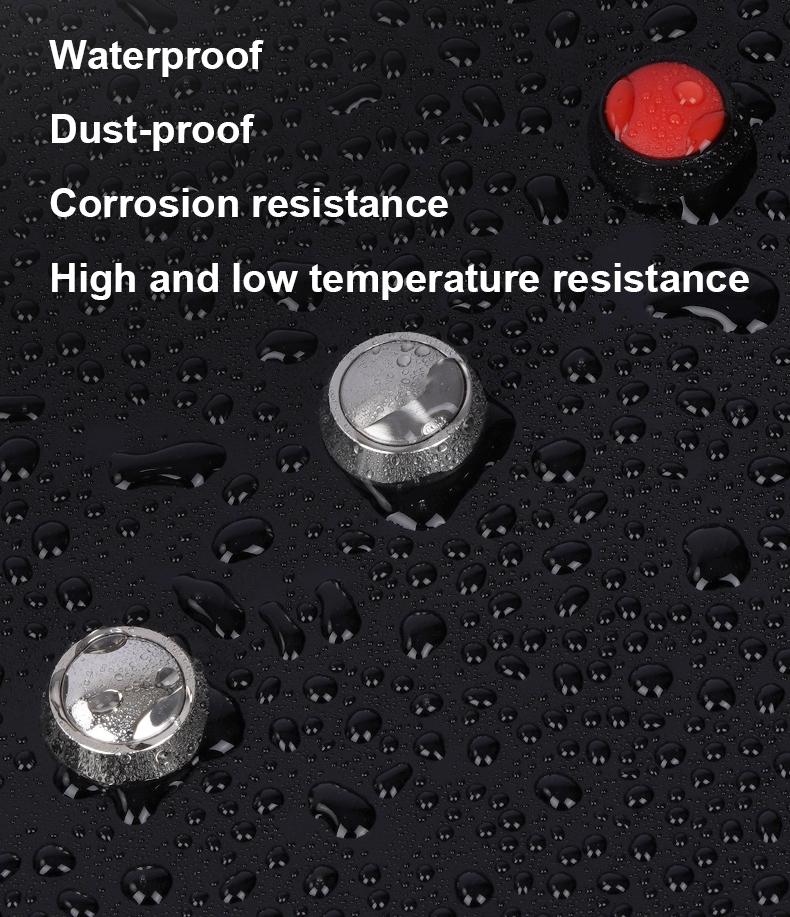

2. Check “Environmental Adaptability” – Medical Spaces Are Tricky

Hospitals and clinics have unique conditions: some areas are humid (like labs), some use strong disinfectants, and others need to avoid electrical interference (to protect sensitive machines like MRI scanners). Your metal button must handle all this:

- Anti-interference: ONPOW’s metal push buttons are designed to resist electrical noise. This means they won’t glitch or send wrong signals when near other medical devices—keeping operations accurate .

- Resistance to harsh conditions: They hold up well against humidity, dust, and common medical cleaners. No need to worry about rust or short circuits, even in high-use areas like operating rooms .

3. Don’t Forget “Safety & Compliance” – Medical Rules Are Strict

Every part of medical equipment must meet strict standards to keep patients and staff safe. For metal push buttons, focus on:

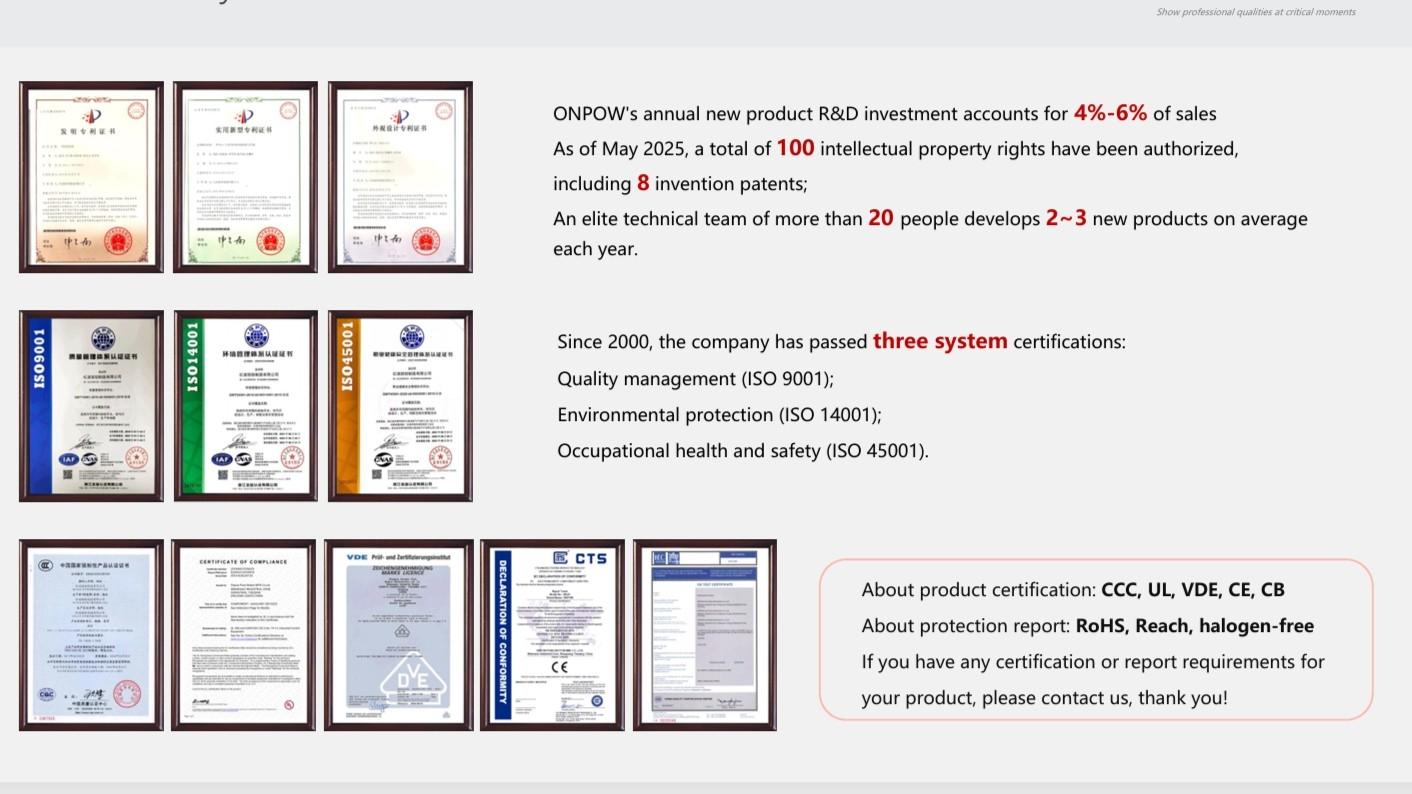

- Certifications: ONPOW’s products have passed global safety certifications like CE, UL, and CB—these are like “passports” that prove they meet medical industry requirements . They also follow RoHS and Reach standards, meaning no harmful chemicals (like lead) are used .

- Low maintenance: Frequent repairs mean taking equipment out of service. ONPOW’s metal buttons have good durability, so they need fewer fixes—saving hospitals time and money .

4. Think About “Fit & Customization” – One Size Doesn’t Fit All

Medical equipment comes in different shapes and sizes: a small portable monitor needs a tiny button, while a large surgical table might need a bigger, easier-to-press one. Look for a supplier that offers:

Multiple options: ONPOW has 18 series of metal push buttons—different sizes, shapes, and colors to match your equipment. Whether you need a round button for a monitor or a square one for a surgical tool, there’s a fit .

Custom solutions: If you have special needs (like a button with a laser-engraved “Start” label or a specific color to match your device), ONPOW does OEM/ODM. They can even make exclusive molds for your equipment—so the button fits perfectly.

5. Look for “Warranty & Support” – Peace of Mind Matters

Medical equipment is a big investment. A good warranty shows the supplier stands behind their product:

ONPOW offers a 10-year quality assurance for their metal push buttons. If something goes wrong (that’s not from misuse), they’ll help fix or replace it .

Global support: They have offices in 5 countries and over 80 sales branches. If you need help (like technical questions or quick deliveries), you can reach them easily—no waiting for days .

Why ONPOW Is a Trusted Choice for Medical Brands

Many big names in medical and industrial fields (like ABB, Siemens, and even medical device partners) use ONPOW’s metal push buttons , . With 37 years of experience, they understand what medical equipment needs—reliability, safety, and flexibility .