When choosing a push button switch for industrial equipment, control panels, or electronic devices, one of the most common questions is: What is the life expectancy of a push button?

The answer matters—because switch failure can lead to downtime, safety risks, and unexpected maintenance costs.

This guide explains what determines the lifespan of a push button switch, what performance you can expect in real-world use, and how to select a reliable option for your application.

Typical Life Expectancy of a Push Button Switch

Most push button switches are rated using two main lifespan indicators:

Mechanical Life (No Load)

- Typically 500,000 to 5,000,000 cycles

- Indicates how many times the button can be pressed without electrical load

- High-quality industrial models often exceed 1 million cycles

Electrical Life (Under Load)

- Usually 100,000 to 500,000 cycles

- Measured while switching current and voltage

- Strongly influenced by load type (resistive, inductive, capacitive)

Electrical life is especially important because it reflects real operating conditions.

Key Factors That Affect Push Button Life Expectancy

1. Load Type and Current

Inductive loads such as motors, relays, and solenoids generate electrical arcing, which shortens the electrical life of a push button switch. Selecting the correct rating or using protection components can significantly extend service life.

2. Operating Environment

Challenging environments can reduce switch longevity, including:

-

Dust and moisture

-

Oil, chemicals, or vibration

-

Extreme temperatures

Using a sealed push button switch with IP65, IP67, or IP68 protection greatly improves durability.

3. Actuation Force and Usage Frequency

Frequent operation or excessive pressing force accelerates mechanical wear. Applications with constant or repetitive use require switches designed for high-cycle operation.

4. Contact Material

Contact materials such as silver alloy, gold-plated, or specially treated contacts improve conductivity and reduce oxidation, directly affecting long-term reliability.

How to Choose the Right Push Button for Long Service Life

To achieve reliable long-term performance, consider the following:

-

Match voltage and current ratings to actual operating conditions

-

Select momentary or maintained operation based on function

-

Choose the appropriate IP rating for the environment

-

Confirm mechanical and electrical life ratings

-

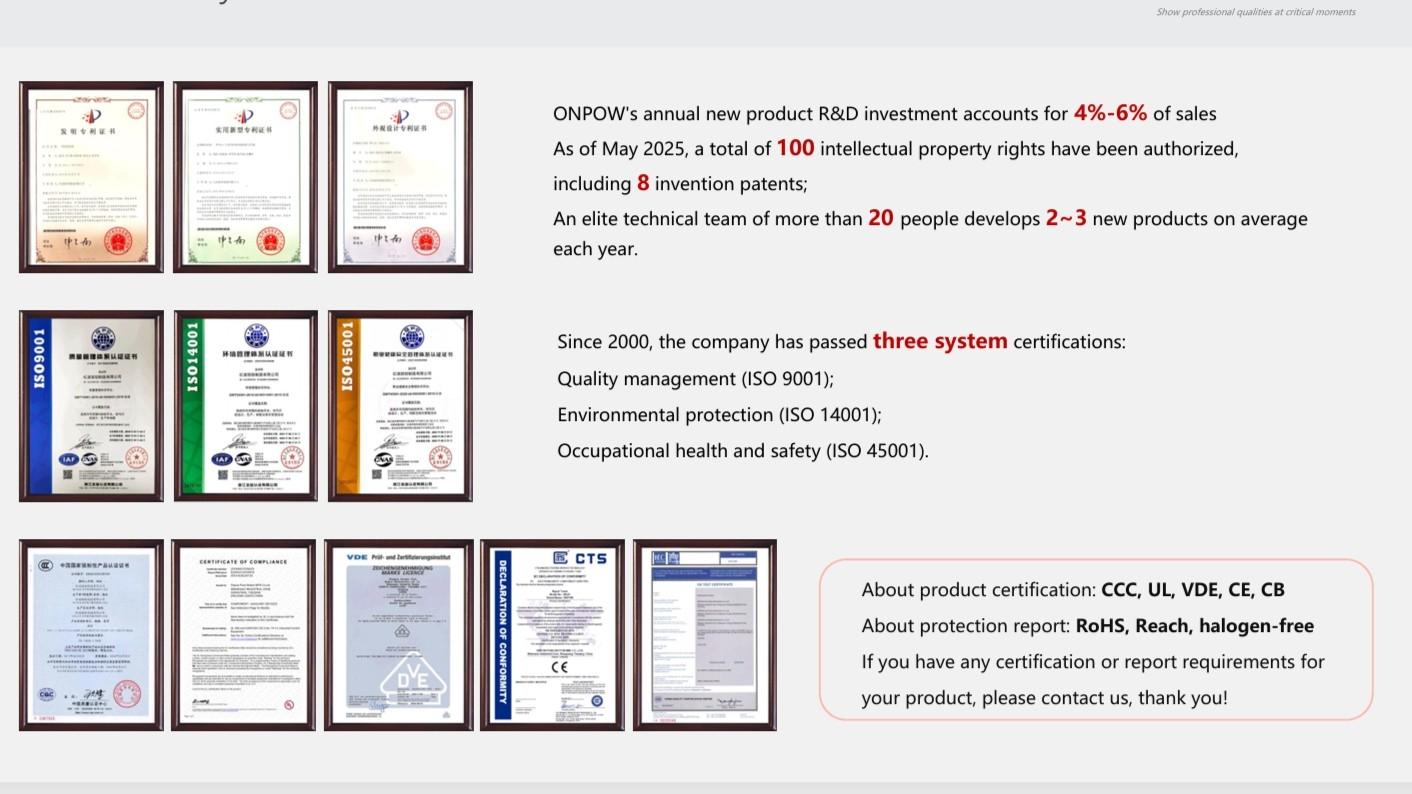

Use products with recognized certifications (UL, CE, RoHS)

A properly selected push button switch can operate reliably for many years, even in demanding industrial applications.

When Should a Push Button Be Replaced?

Common signs that a push button switch is reaching the end of its service life include:

-

Intermittent operation

-

Increased contact resistance

-

Delayed or unreliable response

-

Visible wear or sticking

Timely replacement helps prevent equipment failure and unplanned downtime.

A Note on Industrial-Grade Push Button Switches

Well-established manufacturers design industrial-grade push button switches specifically for the long-term operating requirements of automation equipment, industrial machinery, and control systems. For example, push button switches manufactured by ONPOW often achieve a mechanical life exceeding 1 million cycles, offer protection ratings such as IP65, IP67, and IP68, and carry UL, CE, and RoHS certifications. These features help reduce equipment maintenance and replacement frequency over time.

Final Thoughts

So, what is the life expectancy of a push button?

In most applications, a high-quality push button switch can operate reliably for hundreds of thousands to several million cycles, depending on load conditions, environment, and design.

By understanding lifespan ratings and selecting a switch that truly matches the application, long-term reliability can be improved, downtime reduced, and overall system performance enhanced.